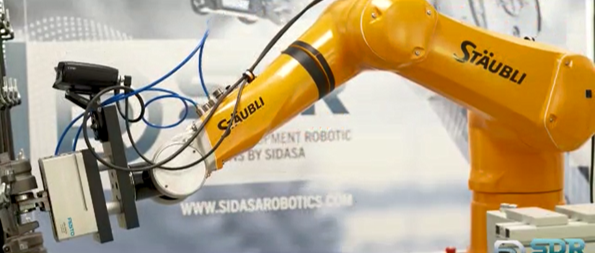

In our SDR business unit, specialized in robotic solutions for industrial processes, we continuously explore technologies that enhance the efficiency and precision of our operations. One of the latest trends we are implementing is 3D vision, applied to automated picking and racking of parts in complex industrial environments.

This solution has proven to be highly effective in identifying and handling metallic parts in chaotic arrangements within containers, overcoming common challenges such as reflective surfaces, irregular shapes, and variable lighting conditions.

Key benefits validating this technology for industrial environments include:

High-precision 3D detection, even on shiny or geometrically complex metallic parts.

Significant reduction of repetitive manual labor and improved ergonomic conditions.

System scalability, easily adaptable to different part formats and sizes without intensive reprogramming.

Seamless integration with collaborative robots, enabling fast deployment in existing production lines.

At SDR, we see these technologies not just as operational improvements, but as a clear path toward intelligent automation. We integrate solutions that combine robotics, computer vision, and energy efficiency to transform traditional processes into more precise, safe, and productive systems.

Another step forward in our vision for the future—where seeing clearly is the key to moving precisely.

SR1 Automated solutions integrating robots, advanced software, and artificial vision to optimize racking and un racking processes aiming to improve:

Key Technology: Thanks to our advanced software we are able to hang parts not only in 1 points but up to 4 points.

To offer the best experiences, we use technologies such as cookies to store and/or access device information. Consent to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Failure to consent, or withdrawal of consent, may adversely affect certain features and functions.