SIDASA Engineering’s SDF business unit is dedicated to bring advanced solutions in electroplating and dip-spin coating systems, providing high-quality, efficient, and sustainable finishing technology for diverse industries.

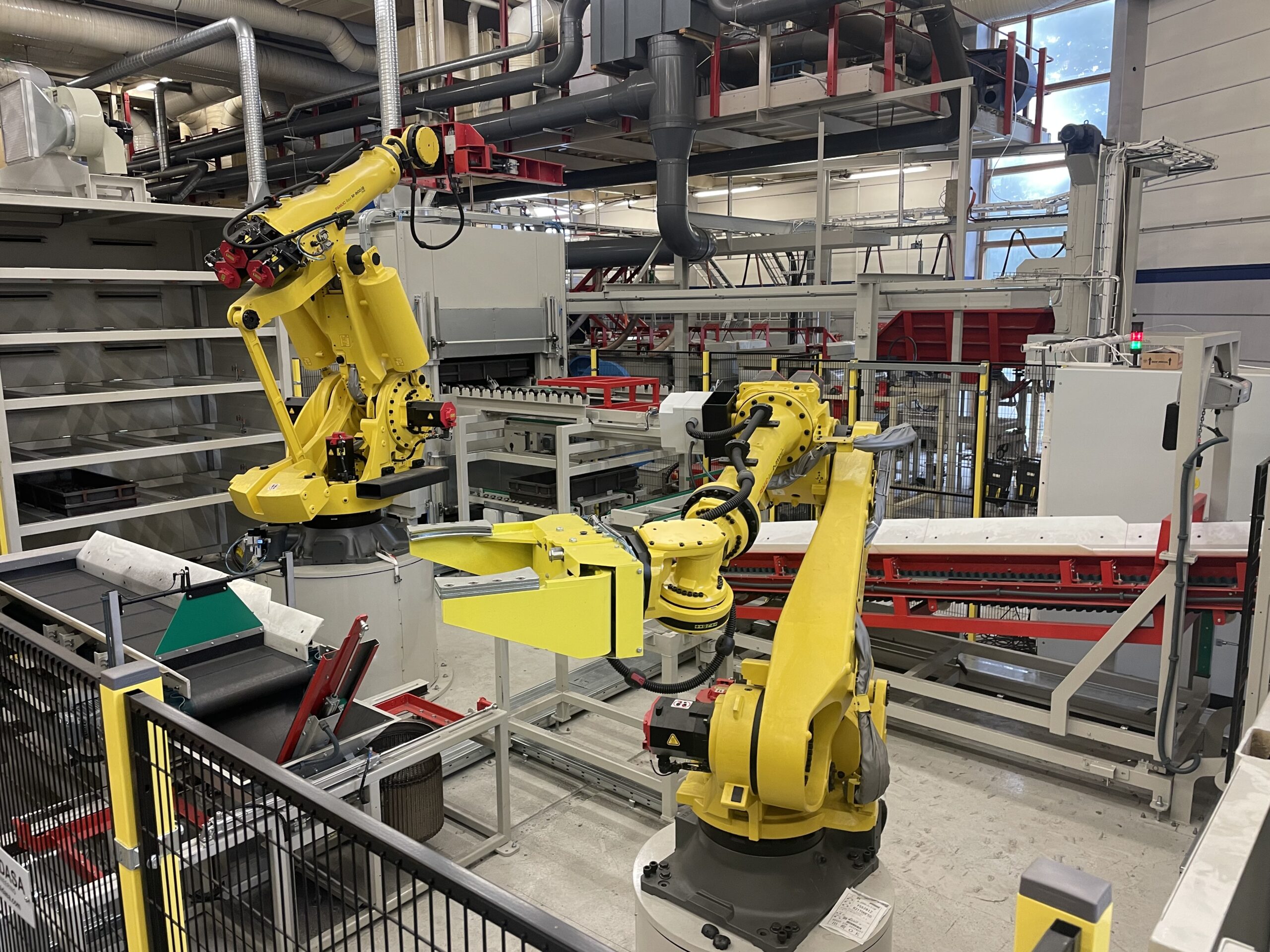

In surface finishing, SDF combines traditional techniques with innovation. We offer both classic hoist systems, known for their reliability, and advanced robotic technology, giving clients flexibility and operation costs savings.

In Dip Spin coating, SDF provides solutions for zinc flakes, sealers and top coat applications with technology ZT providing high rotation PLANETARY eveloped over years of expertise and refinement. As the first to utilize the planetary system in dip-spin applications, SIDASA ensures consistent and high-quality finishes, with each component receiving a uniform and durable coating.

At SDF, we provide solutions for a wide range of industries, including cosmetics, automotive, aerospace, and general manufacturing. Our commitment to excellence and continuous innovation has positioned us as a trusted partner for companies seeking efficiency, quality, and sustainable growth.

Proud to say the planetary coating system was visioned by SIDASA back in 1990. Today the new ZTR will make an step forward.

Developing customized finishing systems tailored to meet our clients' specific requirements.

Monitoring and coordinating all phases of the project to ensure on-time and on-budget completion.

Implementing advanced technologies to optimize water treatment processes.

Expert consulting on selecting the best water treatment solutions and technologies.

Exciting news! We’ve just completed a new, innovative post-treatment process — including sealer application, Zinc flakes technology, and multi-finishing. DR4 solution enhances performance, coating quality , by decresing running costs

Since 1952, SIDASA Engineering has been dedicated to innovating and enhancing industrial painting processes. With our extensive experience, we provide customized solutions that focus not only on top product quality but also on reducing environmental impact and complying with international environmental regulations.

As a global company with branches in Germany, France, and Slovakia, we take pride in supporting international clients in optimizing their production processes. We place special emphasis on minimizing the ecological footprint and adhering to the most stringent standards for environmentally friendly coating techniques.

To offer the best experiences, we use technologies such as cookies to store and/or access device information. Consent to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Failure to consent, or withdrawal of consent, may adversely affect certain features and functions.