SDR is the automation and robotics business units of SIDASA, focused on automating and optimizing industrial processes.

We develop smart solutions for process control, robotization, and production efficiency.

SDR is the SIDASA Group division focused on advanced industrial automation and robotics. We engineer robotic systems that increases OEE, reduce footprint, and lower operational costs.

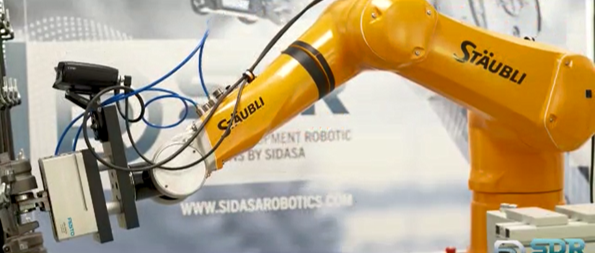

Our dedicated software with integrated camara in the robot wrist ensures speed and precision in every move assisted by AI.

Process Automation

We specialize in automating human tasks using advanced robotics and smart technologies, reducing manual effort and increasing efficiency.

Innovation

Our solutions are designed to replicate human gestures, streamline operations, and minimize repetitive work, allowing your team to focus on higher-value activities.

Better Workplaces, Better Results

By improving ergonomics and working conditions for operators, we help create safer, more comfortable, and more productive environments.

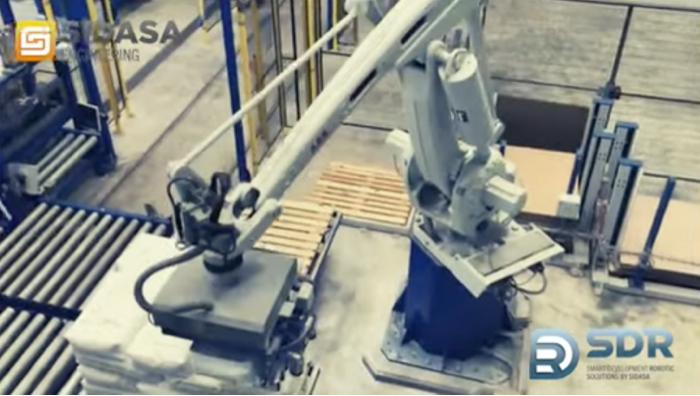

We help manufacturers work faster and save money with easy-to-use end-of-line automation and robotic solutions. Our goal is simple: make automation work for you, so your business can grow and earn more in today’s fast-changing world.

From our earliest innovations, we’ve focused on creating efficient, and reliable automated systems. We tailor every solution to enhance productivity, precision, and consistency across industrial processes.

SDR is a leader in designing safe, effective, and productive interactions between people and machines. Our solutions advance human-robot collaboration by blending intuitive technology with human-centric design, empowering teams with new capabilities.

We prioritize ergonomics to ensure that technology integrates effortlessly into the work environment. Our designs prioritize the health, safety, and comfort of the workforce, making processes not only more efficient but also safer and more sustainable.

Embracing the future of industry, SDR is at the heart of Industry 4.0 transformation. Our solutions utilize intelligent systems, data-driven insights, and advanced connectivity to create a new era of smart, responsive manufacturing.

SR1 enhances traditional industrial processes with innovative robotic and automatic solutions. Not only handling and end of line solutions but also spray technology, focusing on flexibility, efficiency, and customization through advanced robotics, tailored grippers, and an in-house programming team, all while minimizing, OPEX costs, maintenance, footprint, and part-mixing errors

SR1 enhances traditional industrial processes with innovative robotic and automatic solutions. Not only handling and end of line solutions but also spray technology, focusing on flexibility, efficiency, and customization through advanced robotics, tailored grippers, and an in-house programming team, all while minimizing, OPEX costs, maintenance, footprint, and part-mixing errors

Enhance Working Conditions: Reduce physical strain and improve workplace safety.

Increase Predictability: Eliminate uncertainties in manual handling. Lower

Operational Costs: Save on labor and associated costs.

Boost Efficiency: Achieve faster cycle times and higher productivity.

Equipped with 2/6/7-axis robots for versatile and precise handling. Integrated vision systems for accurate recognition and positioning. Fully customized solutions, tailored to your parts and equipment. Proprietary programming ensures seamless adaptation to your needs.

Experience the future of automated racking and unracking with SR2. Save time, cut costs, and achieve operational excellence.

Why Automate?

Enhance workplace safety and conditions.

Reduce costs and uncertainties.

Improve efficiency and cycle times.

How Does It Work?

Advanced 2/6/7-axis robots with vision systems.

Custom-designed grippers tailored to your needs.

Smart solutions powered by innovation and expertise.

Revolutionize your industrial processes with SR3.

Since 1952, SIDASA Engineering has been dedicated to innovating and enhancing industrial painting processes. With our extensive experience, we provide customized solutions that focus not only on top product quality but also on reducing environmental impact and complying with international environmental regulations.

As a global company with branches in Germany, France, and Slovakia, we take pride in supporting international clients in optimizing their production processes. We place special emphasis on minimizing the ecological footprint and adhering to the most stringent standards for environmentally friendly coating techniques.

To offer the best experiences, we use technologies such as cookies to store and/or access device information. Consent to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Failure to consent, or withdrawal of consent, may adversely affect certain features and functions.